Company News 2025-11-07

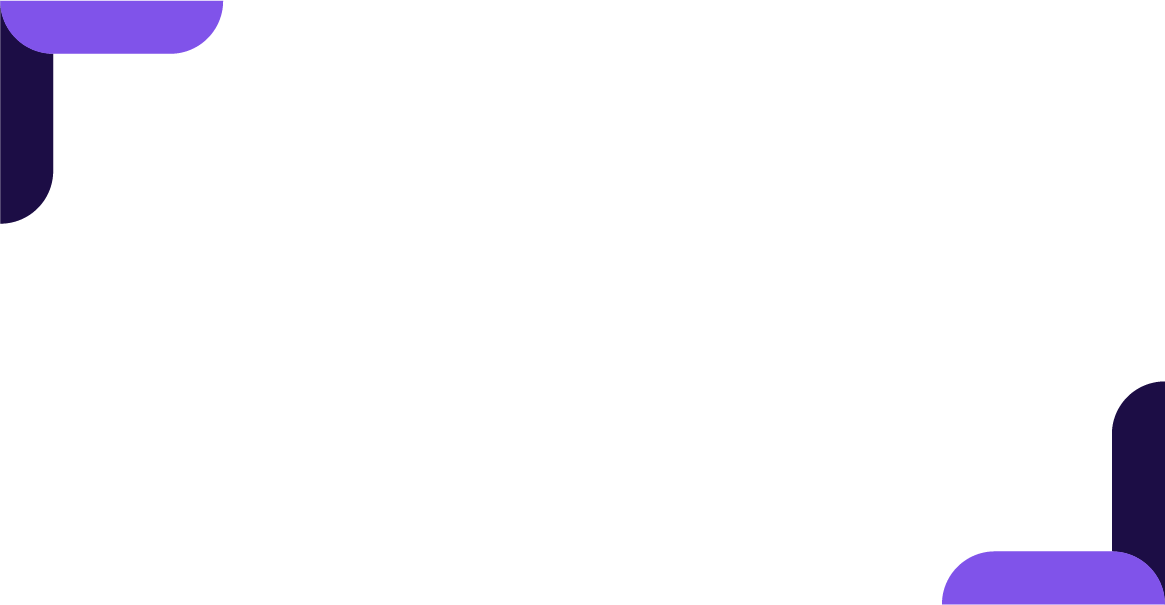

FIMAN Achieves BSI ISO 13485 Medical Device Quality Management System Certification

A New Milestone in Our Commitment to Quality, Built on a Foundation of Excellence

As the international gold standard for quality management systems in the medical device industry, ISO 13485 sets stringent requirements for the comprehensive safety and efficacy control of a company’s entire quality workflow. FIMAN’s certification is not only a testament to its product quality but, more importantly, a solemn commitment to the safety of its consumers.

“Our investment in an ISO 13485-compliant green smart factory and a medical-grade cattle base managed under an EU-standard system ensures that every step, from raw material to final product, is fully traceable,” stated Chen Xinwei, FIMAN’s Managing Director. “These investments were not an option; they were a fundamental requirement to guarantee the safety and efficacy of every unit of collagen we produce. This end-to-end control model was a key point of recognition during the certification audit.”

Smart Factory

As China’s first company to obtain a Class III medical device registration certificate for bovine collagen fillers, building a robust quality system has always been at the core of FIMAN Bio’s development. In Changchun, we partnered with the international automation giant Rockwell to build a world-leading, non-standard, visualized smart factory for collagen. With its end-to-end traceability system and green, sustainable achievements, the factory has been recognized as both a “Jilin Provincial Smart Factory” and a “Green Factory.” Concurrently, we established the industry’s first medical-grade cattle base benchmarked against EU standards. Our proprietary SIM-12 medical cattle are all fitted with electronic ear tags, enabling full life-cycle traceability from birth and vaccination through 18 rigorous inspection stages, thereby achieving ultimate risk management right from the source.

FIMAN Nehe Medical-Grade Cattle Base

Anchoring for the Global Market, Creating a Global Business Card for China

Often referred to as the “international passport” for the medical device sector, the ISO 13485 certification demonstrates FIMAN’s determination and capability to compete on the world stage. The company has now initiated its market expansion plan for Southeast Asia, bringing its active collagen products—backed by this international quality certification—to global markets. This move comes at a critical time for the industry’s upgrade, as the demand for “verifiable safety” in the medical aesthetics collagen market grows increasingly urgent. FIMAN’s certification practice is providing a “Chinese Solution” for the global medical aesthetics biomaterials industry.

Looking ahead, FIMAN will use the ISO 13485 certification as a new benchmark to continue writing its development story, driven by the dual forces of “Quality + Safety.” As Chen Xinwei concluded, “This certification validates the quality and strength of Chinese collagen. We will use it as a cornerstone to build ‘Quality from a Major Nation’ into a consensus of trust that transcends national borders.”