Company News 2025-10-11

Breaking News! FIMAN's First Medical Bovine Industry Base in China Officially Opens

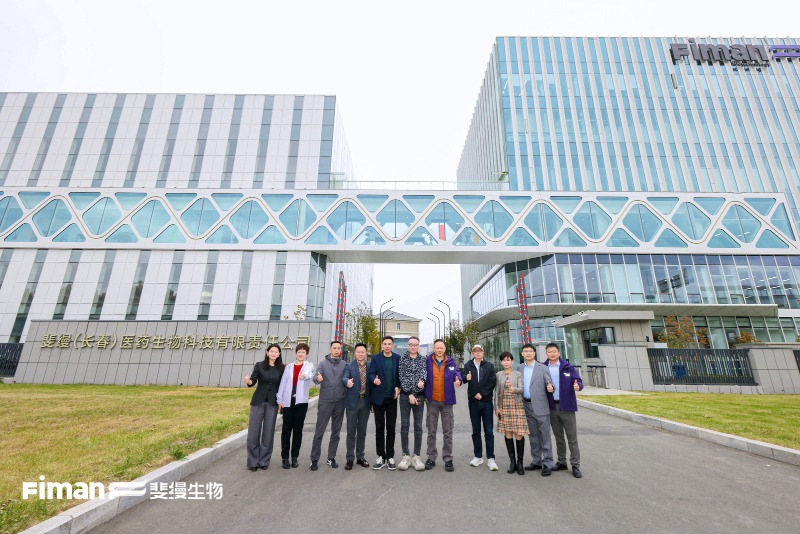

Guest group photo

On October 10th, the completion ceremony of the FIMAN Biological Nehe Medical Cattle Industry Base (hereinafter referred to as "FIMAN Medical Cattle Industry Base") was grandly held in Nehe City, Heilongjiang Province. This marks not only an important milestone in FIMAN's development journey but also a crucial step towards our commitment to "Great Nation Quality Collagen": creating a responsible "full-chain traceability".

Ribbon-cutting ceremony

On the day of the event, Chen Xinwei, Managing Director of FIMAN, Zhao Qing, Deputy Managing Director, and other company leaders, along with Professor Luo Shengkang from Guangdong Provincial Second People's Hospital, Professor Cui Haiyan from Tongji Hospital affiliated to Tongji University, Professor Shi Bing, Chairman of the Plastic and Cosmetic Specialty Committee of the China Association of Non-Public Medical Institutions, Professor Hong Wei, Director of the Cosmetic Department of Sichuan Friendship Hospital, Dr. Hui Xue, Director of the Animal Husbandry Engineering Research Institute of Beijing Dongfang Changxiang Planning and Design Co., Ltd., as well as heads from several leading medical aesthetic institutions such as Meilai, Yixing, and Shenyang Baijiali, and media representatives from Xinhuanet, jointly attended the ribbon-cutting ceremony to witness this milestone moment.

Mr. Chen Xinwei delivered a speech

The safety of medical aesthetics has become a global consensus, and true safety begins at the source. Chen Xinwei, Managing Director of FIMAN, emphasized on-site at the base: "Since its inception, FIMAN has aspired to create collagen that represents 'great nation quality', and quality and safety are our lifelines. To ensure consistency and stability in the production process of biological materials, only by tracing the entire chain from raw materials to the end product can safety be truly guaranteed. The official opening of the Nehe Medical Bovine Industry Base is precisely the implementation of this commitment to 'safety' at the source. We hope that through this new paradigm of 'full-chain controllability' for Chinese collagen, beauty seekers around the world can feel the reliability and strength of Chinese biological materials."

Hardcore strength:

Full-chain traceability system under EU standards

To put this commitment to safety into practice, FIMAN has established a dual-track security system of "hardware investment" and "software management" at its Nehe base. On the one hand, we have fully introduced the EU standard management system to achieve international standardized operations. On the other hand, we have innovatively established a full-chain traceability system for medical cowhide to ensure that every raw material is traceable. To this end, we have invested in the construction of an industrial base covering an area of 35,000 square meters, including a 20,000-square-meter intelligent breeding workshop, supported by a standard biological extraction workshop and a cold chain warehousing center, providing a solid hardware foundation for full-chain controllability.

FIMAN Medical Bovine Industry Base

Upon entering the FIMAN Medical Bovine Industry Base Medical Cattle Industry Base, one is greeted by neatly aligned steel-framed cattle sheds that are clean and tidy, housing SIM-12 medical cattle that are plump and robust. We adhere to self-breeding and self-raising, ensuring control over breed and age from the source. Through precise feeding, we simulate a purely natural grazing environment for them, without any additives or antibiotics.

The guests visited the FIMAN Medical Bovine Industry Base Medical Bovine Industry Base

During the event, the interactive session of "Adopting a Cattle" made this safety "visible and tangible". The guests present personally attached electronic ear tags to the SIM-12 medical cattle developed by FIMAN Medical Bovine Industry Base, adopting their own SIM-12 medical cattle. We presented the control of raw material safety to our industry partners in a vivid, intuitive, and transparent manner:

Exclusive genetic ID card: Each cattle has its own exclusive genetic ID card. The electronic ear tag records all information from birth, vaccination, feed, to medication, and undergoes 18 breeding inspections throughout the process, including being sent to customs for mad cattle disease testing.

Scientific breeding methods: In terms of feed management and drinking water, the use of hormones, antibiotics, non-organic feed, and exogenous animal protein is prohibited. Regular testing of drinking water quality is conducted to better ensure the healthy constitution of the cattle herd.

Guests participate in the "Adopt a Cattle" session

Core questions:

Why do we "put in great effort" to pursue the ultimate source?

The answer is simple: minimize the risk and obtain the optimal proportion of type I and type III collagen.

The complexity of raw materials derived from animals determines that without absolute control over the source, there can be no guarantee of the safety and effectiveness of the final product, let alone eliminating potential hazards from long-term use.

We uphold two lifelines: "activity" and "safety", with a set of standards so rigorous that they border on paranoia:

FIMAN Medical Bovine Industry Base Biotech's self-developed SIM-12 medical cattle

Preserve activity: We adhere to the golden rule of "soaking in physiological saline, maintaining temperature at 4°C, and transporting for 8 hours"

4℃ is the temperature at which water has the highest density. Combined with physiological saline, which has a similar osmotic pressure to body fluids, it provides the most stable "dormant environment" for cowhide cells. We have verified that the tissues of cowhide delivered to the factory still retain biological activity and can even meet the requirements for skin transplantation. Only such raw materials can achieve in vitro self-assembly in subsequent processes, proving their true activity.

Strict safety control: For injection-grade products, the control of microorganisms and endotoxins is of utmost importance

The low temperature of 4℃ can effectively inhibit bacterial reproduction, while physiological saline combined with rigorous cleaning can cut off their "food source" (blood). Our data shows that even in the hottest weather, this system can strictly control the number of microorganisms to the level of 10^5, far below the decay threshold (10^6), thus maintaining product safety from the source.

"In addition to the regular inspection and quarantine standards, we have proactively added special customs inspections for diseases such as mad cattle disease and anthrax. Although there have been no cases of mad cow disease in China, we have listed this as a mandatory inspection item since the first batch of products. This is not to comply with regulations, but stems from our risk management philosophy - to reduce any potential risks to the theoretical minimum," Mr. Chen Xinwei explained while leading guests to visit the base.

Mr. Chen Xinwei led the guests to visit the base

It is precisely based on our ultimate control over the source that we can accurately extract collagen material in a relatively fixed 85:15 golden ratio that meets the needs of the skin from the SIM-12 medical cowhide of 12-month-old cattles at the FIMAN Medical Cattle Industry Base.

The reason why we choose 12-month-old SIM-12 medical cattle is that the collagen ratio in the cowhide at this age is precisely close to the 85:15 ratio found in human skin during the "prime of youth" at the age of 16-18, which consists of 85% type I collagen (providing support) and 15% type III collagen (providing elasticity and moisturization). This is the key to skin firmness and elasticity.

Production line as proof:

Enter the Changchun Smart Factory and witness the strength of a great nation's intelligent manufacturing capabilities

If the Nehe base is the source of quality, then the Changchun factory serves as the modern safeguard for this quality. This smart factory, spanning over 11,000 square meters, stands as China's largest visible collagen injection factory and also the world's largest non-standard automated collagen factory sourced from animal sources. When the guests witnessed its fully automated and digitized management process, they were all deeply impressed and filled with confidence in the quality and safety of FIMAN's products.

Guests visit the FIMAN factory

This confidence stems from our extreme pursuit of production standards. Collagen, which possesses biological activity, is classified as a non-ultimately sterilized product, and its safety relies entirely on strict control throughout the entire production process. This means that everything from raw material processing, sterile operations, to sterilization and filtration, and even the inner packaging materials that come into direct contact with the product, must be sterile. This system is far more stringent, complex, and costly than that for ultimately sterilized products such as hyaluronic acid.

At the molecular level: We rely on over 50 collagen-related patents, including our exclusive PET de-telopeptide patent technology, which removes 100% of telopeptides, eliminating the immunogenicity of collagen and thus eliminating the risk of rejection from the source.

In process control, we utilize a specialized endotoxin detection technology for collagen, with a sensitivity 100 times higher than the pharmacopoeia standard, to monitor the entire production process, ensuring that every step is pure and flawless.

In terms of environment and operation: We strictly adhere to the ISO13485 quality management system, establishing a solid defense line from the automated environment of the smart factory to the sterile standards for every operator.

More importantly, FIMAN is transforming its practical achievements into industry consensus. Currently, the company has collaborated with the Heilongjiang Provincial Department of Agriculture and Sichuan University to jointly develop industry standards for medical cowhide, promoting standardization and transparency in the quality control and traceability mechanisms of medical collagen raw materials. This initiative not only significantly enhances the biocompatibility and batch consistency of collagen materials, but also establishes a new benchmark for the standardized development of the collagen raw material sector in the entire industry, demonstrating the responsibility and commitment of a leading enterprise.